Everyone’s A Freaking Designer

This weekend we were hanging out with an old friend and his classmates, who were in town for the IDSA’s Northeast District Conference. We got to discussing the opportunities that modern prototyping technologies offer and how eventually these tools will enable designers and non-designers alike to contribute directly to the product universe by reducing the barriers to manufacture.

Coincidentally, we also recently encountered an amazing necklace on someone’s neck at a party. It had been purchased via Ponoko, an online service that made a big splash when it launched in 2007, matching consumers with products by both pro and amateur designers.

This led us to take a quick survey of the services available to both makers and consumers. Here is some of the more interesting options we found that allow people to make and sell real, actual products to real, actual people who want them. The options for these sales are amazing.

Everyone’s a designer, everyone’s a customer

Ponoko and Supermarket appear to be strongest designer-to-consumer sites. They actually have an overlap in their catalogs, although Supermarket is a bit more retail-oriented and offers more soft goods. However, the opportunities here for designers and designer-types are pretty amazing; even with the site keeping a fairly hefty percentage of the sale price (almost 50% in some cases), with extremely low or even non-existent setup fees, products can and do make it into the wild, and 100% of money the designer receives is profit. There appear to be some solid successes with the services, too: These beautiful typographic coasters launched via Ponoko, but have since been picked up by the awesome typophiliacs at Veer.

pics: Swallow Beads, Cina USB Drive

Getting Complex

There are restrictions, though. The main manufacturing method used by production-based sites like Ponoko seems to be laser cutting. This limitation does generally lead to products that are flat or made from flat parts.

Until working in 3D becomes cheaper, Moq7 is using an interesting model to let designers experiment with manufacturing more complex forms. Here’s how it works: A designer thinks up a product, say a cool light switch. Moq7 helps the designer figure out the cost of manufacture, then breaks the cost down into a number of individual product sales. Once the required number of people put down money for the future product, the design is manufactured, and everyone is happy. (In the event that the sales do not reach the required number, the money is returned to the investors.)

pics: OFF Light Switch Hook, Cloth Line Clip

Community-Based Creative Ecosystems

Sites like Threadless and Shirt.Woot are hugely popular, successfully encouraging users to submit hundreds or thousands of concepts and voting the best into production. Currently these sites tend towards graphic design and t-shirts. However, the communities are vibrant, and there is no reason that this format could not flourish for product design in the long-term.

pics: We’re On The Same Level print, Playing God t-shirt

Customize it for yourself, and maybe sell it

CafePress and the hipper Zazzle allow users to piece together their own products from a catalog of options, plus the users’ own graphic designs. Zazzle, for instance, offers a variety of skateboard decks that can be customized in numerous ways. Blurb and StyleShake allow the same template-based variation for books and clothing, respectively.

Generally these sites allow you to sell your versions to others, but the possibilities are more limited than sites like Ponoko: Zazzle users can ideate only within the finite options, whereas Ponoko sells a laser cutting service, and lets you use the service almost any way you want.

pics: custom Flip camcorders, custom skateboard decks

Prototypes Are The Product

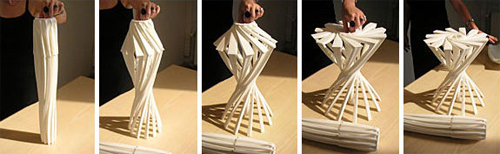

Sites like Quickparts and ShapeWays offer high quality rapidly-prototyped parts. ShapeWays in particular is geared for individual designers, although it doesn’t currently have a retail front. Designers are taking advantage of the creative possibilities of these processes with growing frequency: Patrick Jouin recently developed a collapsing stool with integrated hinges that can only be produced by machining a single piece of material via rapid prototyping technology.

However, as we mentioned, this kind of technology is out or reach for most people; not only is the cost of production high (though dropping), but the 3D software used to create the objects are very expensive. However, with the inevitable development of cheap or even free tools, like Google’s SketchUp, this will not be the case forever.

pic: Jouin’s One Shot Stool

Not all of these design-driven business models will survive the harsh evolutionary process they are being put through. But the fact that these processes are even options right now, at this very second, is absolutely exciting.